Image

Confer Plastics share it's American dream at its annual open house Wednesday.

The 50-year-old, Witmer Road, North Tonawanda plastic blow molder is thriving and seems to roll through every crisis it faces.

Through Covid, a supply chain crisis and losing a major kayak contract, the manufacturer seems to roll with every punch.

There is no hiding the place being a big, noisy, smelly manufacturing facility, a proudly family owned business prominently displaying the flag and supporting American manufacturing since long before that became a political thing.

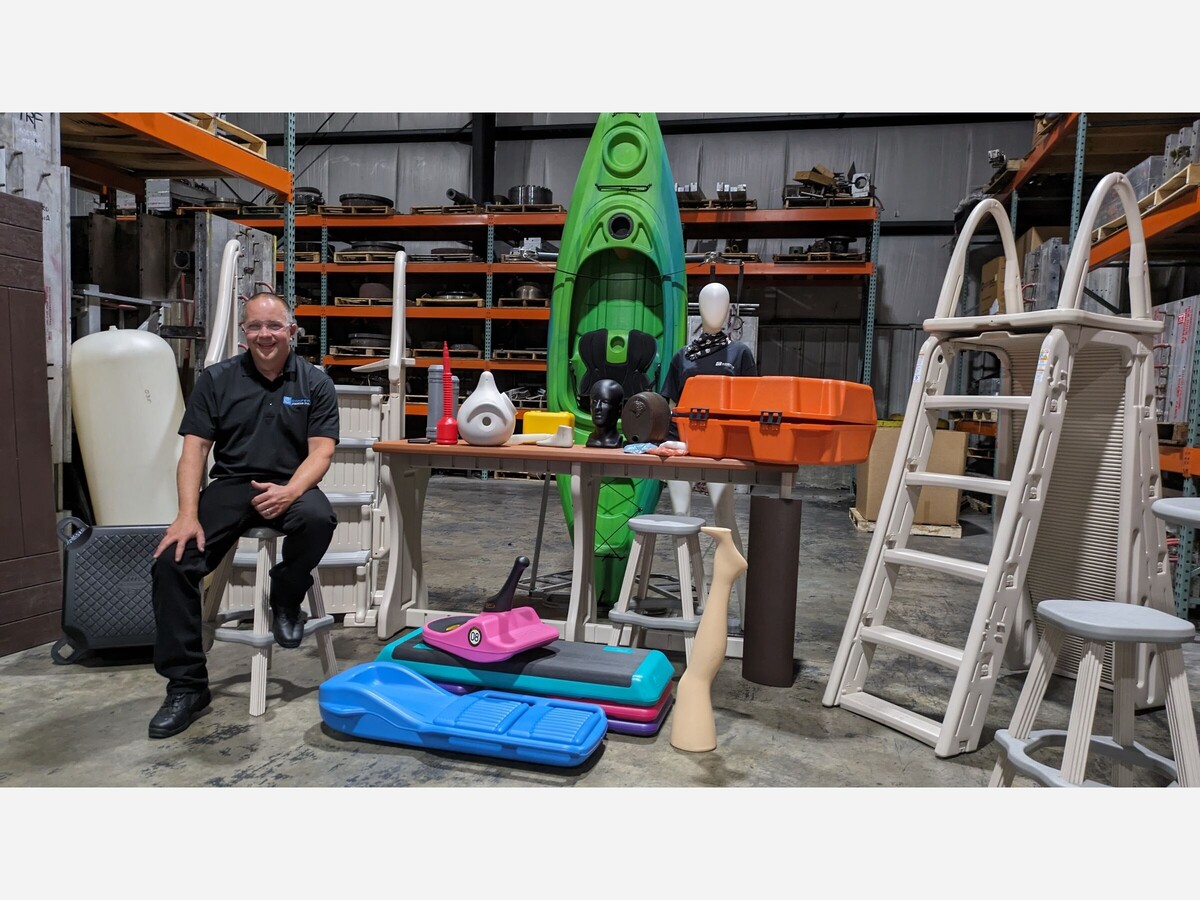

Our tour began with Bob Confer, president, who runs the place . Bob talked to our group of 10 about the Confer story, from founding by his grandfather Ray to being run by his dad Doug and today continuing in the family with Bob, and his sister Connie, who runs human resources.

Bob sat next to a display of products representing his family’s business, everything from a children's sled to a funnel, a pool ladder, a purple martin house and a suitcase featuring a live hinge which was one of the only things they could make during the pandemic shutdown. The case is a testament to surviving covid.

The hinge was Ray’s patent, since expired. You use it daily. It’s on that clamshell takeout container as well as the food package from Wegmans.

The pool ladder, mostly used for above-ground adaptations, is another star. It has a safety measure borne of a design engineer who was into antiques.

He was restoring a desk with a roll-top when inspiration struck. The accordion feature, rendered in plastic, could run on rails parallel to the ladder steps and be locked to limit access so an unattended child can't ascend and fall in.

The design is so ingenious the Chinese have stolen it because disloyal consumers don’t care where things are made.

Confer, active on social media in posting about his family, business and nature, recently posted an advertisement ripping off the pool ladder design that even included a link to the Confer Plastics Website for assembly instructions.

A guest on our tour was Brian Gwitt, of Woods Oviatt, Confer’s counsel, if anything could be done about such blatant commercial theft and patent infringement.

Gwitt said the law is tricky but it is possible to stop such pirated designs from being accepted at the port.

Despite his social media acumen, Bob is a bit of a luddite. He carries a flip phone. He also has two pens, paper, and a paper calendar in his pocket and given a choice would always rather be out for a hike or in the woods.

At one point, the business kicked out 100,000 completely built kayaks a year. That contract went away because a private equity firm bought out the brands.

“Private equity” is an ugly term in Confer land. The Kayak story is one that repeats itself. Investors buy out a family business because of a 5th C, “Capitalism” and a 6th “Cash.” Confer comes first in the 4 Cs because it is a family business.

Too often, private equity doesn’t understand the value of Confer, Customers, Coworkers and Community. They only value Customers. Confer (family) does not matter. Coworkers and Community are replaceable, at least in the eyes of those looking for a quick buck. Cash and capitalism are king.

Only it does not always work out. And it did not for the private equity kayak invetors. The new owner of the kayak brand took a predictable course and lasted 18 months.

One of the previous kayak manufacturers decided to get back in the business and had lots of money to do so. The market remains. So do the molds. Confer is suddenly making 50,000 kayaks a year again, but only the part they make is the shell. No more having 11 people involved mounting seats and tying ropes.

Bob is passionate about his coworkers, especially the ones new to America, and about New York State.

The company employs about 150 people. About 1 in 5 were born in another country with a good representation of people from impoverished, famine stricken and often war-torn places like Myanmar and Sudan.

“They came from a literal hell on earth to heaven on earth, which is America,” Confer said.

On our tour, we watched laborers pulling product from molds, trimming excess and loading the overage onto cooling trays to be fed into shredders and recycled. Think of plastic pie crust with just a little left over, only sent to use on a boat dock rather than falling useless in a landfill.

Another success story Bob told us was that of a boy who wanted a backyard hockey rink. He was 16. He didn’t understand all the trips to Home Depot and how complicated it was.

He approached Confer, designed his rink, sold many, attended Harvard, got his bachelors and MBA and is now a 26-year-old debt-free multimillionaire. It is the American dream for Americans, too.

Our tour guide, Cody Gillette, said he started as a machine operator 9 years ago. Today, he works as an inventory specialist focused on production planning.

He pointed to silos scattered around the facility as a testament to why New York is a great place. In 2021, a deep freeze gripped the unregulated electric grid in Texas where a major supplier was forced to shut down. Confer only had enough raw material to keep running for a week.

In response, the company added additional storage capacity. Gillette said they now have about 30 days of supply on hand. The incompetence of the Texas government won’t impact the supply chain again the same way.

Some products, like the sides for a hot tub, are easy to product and simple, with fewer parts. Other things, like a kayak or a pool ladder, take more care. Making sure the right parts are in the right place, at the right time in the manufacturing facility is a challenge. That’s Gillette’s gig.

A few highlights stuck out. First, we were touring on 2nd shift. There seemed to be a ton of people of Asian heritage, working diligently, catching product from molds, punching holes, trimming excess and recycling waste. No one seemed miserable and our guide, as well as Bob, started on this floor doing the most menial jobs you could find in a meritocracy.

Every open house guest went home with a goody bag, a Confer funnel and a plastic bench.

The American flag is everywhere at the facility and has been since long before patriotism became cool.

After our tour, guests shared an outdoor buffet, with the predictable, as in dogs and burgers, as well as some food that paid homage to the heritage of the workers, like beef curry.

Doug Confer sat with us and chatted about how much of what he has, from the family farm in Gasport to the plastics company, is attributable to his parents even as the next generation controls the business and the one after is in the wings.

If you want to see what is right with the economy, and in manufacturing in New York State, Confer Plastics is a great place to start.